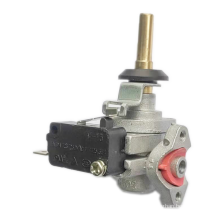

High Round metal pushbutton switch waterproof micro switch

Click on the follow link to find out more information: https://www.dongyeinjectionmolding.com/micro-injection-molding/

Company Info

- Company Name: Suzhou Dongye Precision Molding Co.,Ltd.

- Representative: Hanpan

- Product/Service: Injection Molded Parts , Injection Mold , Injection Molded Parts Assembly , Custom Molded Parts , Custom Injection Plastic Molding , Custom Plastic Parts

- Capital (Million US $): 3000000RMB

- Year Established: 2002

- Total Annual Sales Volume (Million US $): US$10 Million - US$50 Million

- Export Percentage: 41% - 50%

- Total Annual Purchase Volume (Million US $): US$5 Million - US$10 Million

- No. of Production Lines: 5

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: Plant No. 4, No. 52, Jinqiao Industrial Park, Mudu Town, Suzhou City

- Contact Person: Mr. hanpan

- Tel: 86--18862398807

Premium Related Products

Hot Products

Special for Generator 4 in 1 generator monitor customized generator partsTR-BAS15-2USB UL and CUL listed RECEPTACLE with USBBAS15-2USB UL and CUL listed receptacle with USBYGC-013 Approved UL94-V0 plastic mini electrical junction boxYGC-014 Electronic instrument enclosures usa socket plastic junction boxYGB-093 BAREP High quality 60HZ 15A wall switch socketYGC-009 Household decorative switch wall plates with socketsBAREP BAO-002 PA6+30% wall plate american plastic switch coverBAO-001 BAREP Outdoor push button lighting american switch cover15 Amp, 120/277 Volt, Decora Rocker Single-Pole AC Quiet Switch, Residential Grade, Grounding, White1-Gang Decora/GFCI Device Decora Wall plate, Standard Size, Thermoset, Device Mount, White15-Amp Single Pole Switch, WhiteAmerican stype wall switch barepCUL listed GFCI receptacle NEMA5-15 Barep with tamper wall outletGFCI receptalce NEMA5-15 BarepGFCI Safety Circuit 15A 125V wall outlet socket